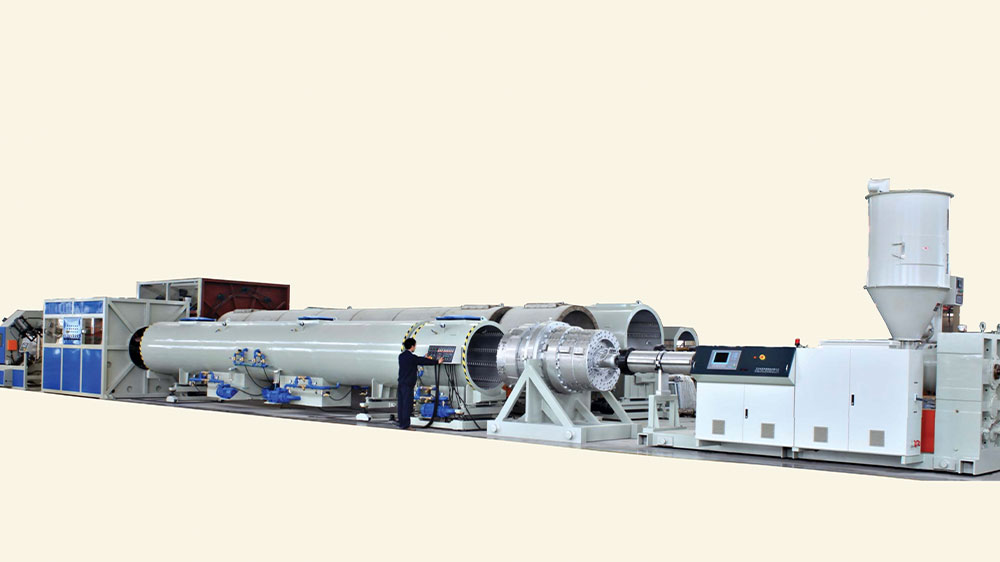

PE PP PC yeeb nkab raj extrusion tshuab

Khoom Description

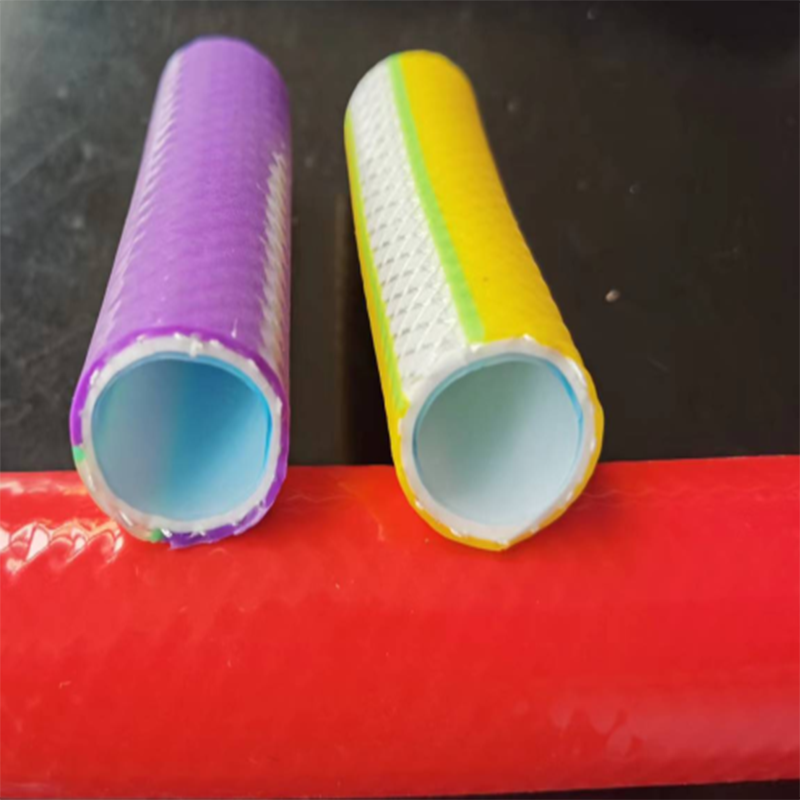

>> PE Yeeb Nkab Extrusion Tshuab yog siv los tsim cov kav dej ua liaj ua teb, cov kav dej, cov kav dej, cov kav dej, cov kav dej, cov kav dej thiab lwm yam.

>> Cov yeeb nkab muaj qee yam zoo heev xws li cua sov resistant, aging resistant, siab mechanical zog, ib puag ncig kev nyuaj siab tawg resistant, zoo creep resistant, thiab lwm yam. suab nrov, Gravimetric dosing unit thiab ultrasonic thickness qhia tuaj yeem sib sau ua ke raws li cov neeg siv khoom xav tau kom nce qhov tseeb ntawm cov kav dej.

>> Tig cov tshuaj tseem ceeb tuaj yeem muab tau, xws li laser tshuab luam ntawv crusher, shredder, dej chiller, cua compressor thiab lwm yam. kom ua tiav qib siab thiab tsis siv neeg raj ntau lawm.

>> Cov txheej txheem ntws: Raw khoom + Master Batches → Sib tov → Nqus Feeder → Yas Hopper Drier → Ib leeg ntsia hlau extruder → Co-extruder rau xim hlua & Ntau txheej → Pwm → Nqus Calibration Tank → Txias Dej Tank → Haul-off → Tsis muaj plua plav Cutter → Ob chav / Ib leeg disc Winding / Stacker → Cov khoom kawg soj ntsuam & ntim

1. Ib leeg ntsia hlau Extruder

Ib leeg-ntsia hlau extruder tuaj yeem tsim ntau yam khoom yas xws li zaj duab xis, yeeb nkab, board, braid, siv thiab granules.

2. PE yeeb nkab tuag taub hau

>> Tsim nyog rau HDPE, LDPE, PERT, PP, PPB, PPH, PP-R, PS yeeb nkab ntau lawm

>> Txoj kab uas hla ntawm Ø16 txog Ø1600 mm

> > High melt homogenity

> > Tsis tshua muaj siab txawm tias muaj cov zis siab

> > Melt channel tis system

> > nruab nrog lub tshuab cua sov

> > yeeb nkab taub hau nqa tau yooj yim

>> Cov taub hau yeeb nkab yog tsim raws li daim ntawv thov.

>> Ib qho yooj yim txij nkawm ua tsaug rau qhov optimized thiab proven tsim tsim.

Nyob rau hauv xyoo tas los no, kev ua lag luam ntawm cov yeeb nkab yas yog tsim nyob rau hauv Suav teb.PE, PPR thiab UPVC yeeb nkab ua lub luag haujlwm tseem ceeb.Qhov twg txoj kev loj hlob ntawm PE yeeb nkab yog qhov zoo tshaj plaws.PE yeeb nkab muaj ntau yam kev thov.cov khoom siv dej thiab cov kav dej yog ib qho ntawm cov kev lag luam loj tshaj plaws.

Peb tab tom siv tag nrho cov ntws ntws cov txheej txheem txhawb nqa thiab tshem tawm cov khoom siv

Cov qauv tsim channel tau zam qhov chaw tuag thiab khaws cia.

Qhov kev tsim kho kom zoo ntawm cov dej ntws ua rau nws muaj kev cuam tshuam zoo dua.

Yooj yim rau assemble thiab disassemble.

Lub tshuab nqus tsev calibration tank

>> Tsim nyog rau PE yeeb nkab ntau lawm

>> Txoj kab uas hla ntawm Ø16 txog Ø1600 mm

>> Ntev mus txog 12000mm

>> 304 stainless hlau nrog pleev xim rau sab nrauv

> > Cov tshuaj tsuag dej tshwj xeeb yog nyob ntawm qhov zoo tshaj plaws kom txias cov yeeb nkab kom zoo

>> Tshwj xeeb thiab yooj yim kho yeeb nkab txhawb nqa rau txhua txoj kab uas hla

> > Lub tshuab nqus tsev thiab cov twj tso kua dej tuaj yeem ua haujlwm yam tsis muaj kev tu ncua ntev

>> Cov chav da dej tshwj xeeb tuaj yeem tsim los rau kev tsim khoom tshwj xeeb

Tshem tawm lub tshuab

>> Cov kav dej ntau ntawm Ø16 txog Ø1600 mm

> > siab rub quab yuam tsis poob cov kav dej

> > nruab nrog 2, 3, 4, 6, 8, 10 lossis 12 kab ntsig raws li daim ntawv thov

>> Servo lub cev muaj zog tsav tsheb rau muab kev ruaj khov torque thiab khiav

> > Motorized positioning ntawm cov kab ntsig qis

>> Kev ua haujlwm yooj yim

> > Ua tiav kev tiv thaiv kom muaj kev nyab xeeb siab tshaj plaws

>> Cov saw conveyors nrog tshwj xeeb roj hmab ncoo ntawm chains uas tsis muaj cim rau ntawm cov yeeb nkab.

>> Synchronization nrog lub extruder ntsia hlau ceev tso cai rau cov khoom ruaj khov thaum hloov cov khoom ceev

Txiav qhov system

>> Tsis siv neeg synchronization nrog extrusion ceev

> > Planetary nruab nrog disk thiab milling cutter rau txiav thiab chamfering

>> Chip-dawb nruab nrog disk hniav kom ntseeg tau tias soomth txiav nto yam tsis muaj plua plav

>> Kov npo tswj vaj huam sib luag

> Tag nrho cov kev txav yog motorized thiab tswj los ntawm kev tswj vaj huam sib luag

>> Cov yeeb nkab thaiv nrog siv universal clamping rau kev ua haujlwm yooj yim

> > Hom txiav txiav yog xaiv nyob ntawm cov yeeb nkab

> > kev tu ncua tsawg

>> Ua tiav kaw thiab ruaj ntseg tshuab kom muaj kev nyab xeeb siab tshaj plaws

Khoom Paramenters

| Txoj kab uas hla (mm) | Extruder qauv | Max.Peev xwm (kg / h) | Max.lineal ceev (m / min) | Extruder zog (KW) |

| Ф20-63 | SJ65/33 | 220 | 12 | 55 |

| Ф20-63 | SJ60/38 | 460 | 30 | 110 |

| Ф20-63 Dual | SJ60/38 | 460 | 15 × 2 | 110 |

| Ф20-110 | SJ65/33 | 220 | 12 | 55 |

| Ф20-110 | SJ60/38 | 460 | 30 | 110 |

| Ф20-160 | SJ60/38 | 460 | 15 | 110 |

| Ф50-250 | SJ75/38 | 600 | 12 | 160 |

| Ф110-450 | SJ90/38 | 850 | 8 | 250 |

| Ф250-630 | SJ90/38 | 1,050 ib | 4 | 280 |

| Ф500-800 | SJ120/38 | 1,300 ib | 2 | 315 |

| Ф710-1200 | SJ120/38 | 1,450 ib | 1 | 355 |

| Ф1000-1600 | SJ90/38 SJ90/38 | 1,900 ib | 0.6 | 280 280 |