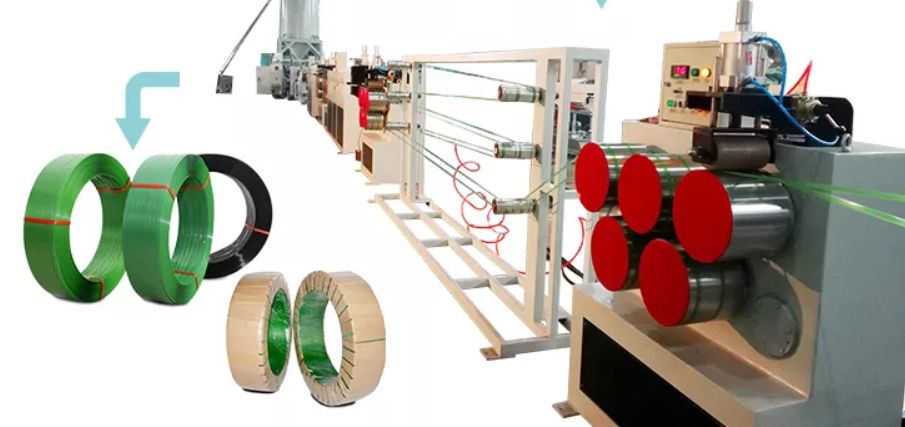

PET ntim siv cov kab ntau lawm

I. Basic parameters:

Kev Ua: 100% PET lub raj mis lossis tshiab (viscosity 0.75 lossis ntau dua)

Technical parameters rau raw khoom

| Raw khoom A: 100% | |

| lub voj voog khoom | PET lub raj mis chip fragments |

| Raw khoom zoo li | Qhov siab tshaj plaws txoj kab uas hla ntawm 8-10mm |

| tuab | > 400 micron |

| IV | 0.75-0.9 dl / g |

| ceev | 0.35-0.40kg / dm3 |

| Cov dej qub | <1% |

Specification dav ntawm 9-19mm (peb niaj hnub)

Pob siv lub thickness ntawm 0.6-1.2mm

tawg lub zog 40-45kg / mm²

Extensibility 10-15%

Nyem tawm ob peb feeb

Extrusion Volume, Max.180-220Kg / h

Kab ceev yog 120m / min 2

Kev siv fais fab yog AC 380v / 3HP / 60Hz

ntsia muaj peev xwm 152kw (ua haujlwm muaj peev xwm txog 95kW)

Cov neeg ua haujlwm, 1-2 tus neeg

Loj: 40m × 2m × 3.5m

Ob, cov kab ntau lawm

| xaj naj npawb | npe | qauv | kom muaj nuj nqis | lus hais |

| 1 | Qhuav lub precrystallization system | 1500L | 2set ib | |

| 2 | dehumidifier | 1set ib | ||

| 3 | ib leeg ntsia hlau extruder | SJ-90/30 | 1set ib | |

| 4 | Kem hloov net | 1set ib | ||

| 5 | tswj ntim twj tso kua mis | 1set ib | ||

| 6 | Flow der taub hau (pwm) | 1set ib | ||

| 7 | bosh | 1set ib | ||

| 8 | Thawj tsib-yob preheater | 1set ib | ||

| 9 | Tensile qhov cub (kub lub thawv) | 1set ib | ||

| 10 | Thawj stretch tshuab | 1set ib | ||

| 11 | Qhov thib ob stretch tshuab | 1set ib | ||

| 12 | npib zeb | 1set ib | ||

| 13 | Tighten cov khoom siv cua sov | 1set ib | ||

| 14 | bosh | 1set ib | ||

| 15 | Peb-roller tsheb laij teb | 1set ib | ||

| 16 | PLCDual-chaw nres tsheb winder | 2set ib | ||

| 17 | hluav taws xob tswj qhov system | 1set ib |

| 1. Ua los ntawm 202 # stainless hlau, nrog ob lub thoob lub cev tsim, 1.5MM² txheej sab hauv, 1.5MM² txheej txheej, thiab lub qhov rais pom tau teeb tsa ntawm lub thoob lub cev | |||||

| 2. Lub tshuab ziab khaub ncaws muaj peev xwm yog 1200KG, lub zog hluav taws xob thermal yog 4KW, thiab lub zog sib xyaw yog 5.5KW | |||||

| 3. Siv 3HP deceleration lub cev muaj zog tig |

|

|

| ||

| 4. Nruab nrog scaffolding, uas yog ua los ntawm 3.0T txias phaj |

|

| |||

| 5. Hauv qab yog nruab nrog cov khoom ncaj nraim rub tawm qhov chaw nres nkoj |

|

|

| ||

| 6. Ntxuav lub qhov rooj tsim thiab ntxuav lub qhov rooj |

|

| |||

| 7. Qhov nruab nrab sib xyaw pas nrig txais ¢ 50 stainless hlau seamless yeeb nkab, thiab cov hniav sib tov yog ua los ntawm 3.0 reinforced stainless hlau phaj. | |||||

| 8. Txais Huawei cua sov ncig kiv cua ua qhov chaw xa cua kub |

|

| |||

| 9. Nruab 50 ~ 300 ℃ overtemperature tiv thaiv |

|

|

| ||

| 10. Siv hluav taws xob tswj vaj huam sib luag, tsis siv neeg thiab ua haujlwm tsis tu ncua, ib hnub nyob rau hauv 24 me me adjustable pib |

| ||||

| 11. Muaj qhov qhia txog kev sib tsoo thiab kub dhau, thiab qhov sib txawv ntawm qhov kub thiab txias ntawm PID kub tswj hom yog me me. |

|

| |||

| 12. Blower-blowing hom tsim los ua kom qhov kub thiab txias dua |

|

|

| ||

13. Cov txheej txheem ua haujlwm

| 1 | Lub zog rau hluav taws xob | AC 415V ± 10% 60HZ 3P + N |

| 2 | dej txias | 20 ℃ 0.2 ~ 0.3Mpa 300L / min |

| 3 | Qhuav raw khoom | Cov ntsiab lus dej yog 0.45% ua ntej PET kom qhuav |

14. Ntau lawm muaj peev xwm

| 1 | ziab lub zog | PET 500Kg / h (sau ntom ntom: 0.5T / m³) |

| 2 | muaj peev xwm xa khoom | PET ≥ 500Kg / h |

| 3 | Hloov qhov nrug | L≥6m H≥6m |

| 4 | Installation Rhiav | Sab hauv tsev 0 ℃ ~ 30 ℃, txheeb ze av noo 20% ~ 70% |

| 5 | Cov khoom siv xim | KH Txheem xim lossis cov neeg siv khoom xav tau |

1) dehumidifier

|

| |||

| Lub zog noj ntawm regenerative windmill yog 2.2KW, thiab lub zog noj yog 20KW | ||||

| 3. Tsis siv neeg microcomputer digital controller tuaj yeem tau txais cov dej ntws ruaj khov ntawm huab cua qhuav. | ||||

| 4. Txais yuav LED interface tso saib qhov system thiab tsis siv neeg ua haujlwm tsis zoo. |

| |||

| 5. Sweden tau import dehumidifying log nrog lub neej ua haujlwm ntev. |

| |||

| 6. Haum rau qhov zoo tib yam thiab kho qhov muag antipyretic thiab ziab. |

|

| ||

| 7. Lub cev muaj zog rov qab theem thiab kev tiv thaiv overload. |

|

| ||

| 8. Nws muaj overtemperature tswb thiab fault zaub muaj nuj nqi, yooj yim sab hauv qauv, txhaum hauv qab, yooj yim txij nkawm. | ||||

| 9. Siv cov kiv cua siab ua kom muaj zog thiab rov ua kom muaj cua txias kom ntseeg tau tias lub tshuab ua haujlwm li qub. | ||||

Lub tshuab no yog siv los ua tsiaj pluaj, tsiaj ntim pluaj.

Txais yuav lub plc tswj tag nrho cov kab ua auotmatic ntau lawm

nws siv lub twj tso kua mis melting thiab siab sensor xyuas kom ruaj khov thiab pluaj zoo tswj

Cov khoom siv raw uas koj tuaj yeem siv tau yog 100% rov siv dua cov tsiaj flakes los ntawm cov khoom pov tseg tsiaj, lossis cov khoom siv nkauj xwb los yog sib xyaw ua ke.

Qhov zoo:

1.Siv 100% Recycled PET Flakes kom txo tau tus nqi

2.Zoo dehumidifer drying system (Crystallization system xaiv tau) los xyuas kom meej cov khoom sib npaug ntawm lub tshuab ziab khaub ncaws kom ua tau zoo strapping

3.Tshwj xeeb tsim kub sib sau tensile tank kom zoo sib sau, sib npaug dav, ncaj pluaj

3)cylindrical net hloov

Qhov chaw cua sov cheeb tsam 2

Lub zog cua sov: 2KW 2

Khoom siv: PET (lub raj mis ntawv) (0.7-0.95)

Lim theem: 40/80/120 mesh (425/180/125um)

4) ntsuas twj

Twj lub cev: sab hauv ntws channel ntawm nitride cuab yeej steel rau daim iav kho

Iav: cov hniav zoo nkauj ncaj cov hniav lossis oblique hniav cuab yeej steel / tshwj xeeb alloy rau daim iav kho

Lub tes tsho ncej: cuab yeej steel / tshwj xeeb alloy

Cov txheej txheem cua sov: cua sov ntawm cov dej ntws

Txias hom: lub taub hau-kawg cua txias system

Axis duab: biaxial tsav, txias nrog dej

Axial foob: muab kauv tawm

5)Flow Extension tshuab taub hau (pwm)

Ua los ntawm cov pwm zoo steel, compact qauv, tsim nyog kev sib txuas thiab yooj yim hloov.Hloov pwm lub qhov ncauj los tsim 9-19mm specification khoom.

Flow channel nto plating nyuaj chromium thiab polishing kho, thickness 0.03-0.05mm, hardness HRC50-60, polishing raug 0.02-0.06um.

Sab nrauv yog chrome plated txheej 0.02-0.03mm kom yooj yim txij nkawm thiab tiv thaiv xeb.

Number ntawm strips: 2 strips

Stainless hlau cua sov pas nrig sab hauv cua sov, stainless hlau cua sov nplhaib txuas caj dab cua sov, hwj chim 4kW.

Siab-sensing cheeb tsam ntawm 0-350bar

7) Lub dab dej txias

Kev kho qis: phau ntawv nqa

Kev tswj qhov kub thiab txias (quantity) cheeb tsam 1

Stainless hlau cua sov yeeb nkab thiab stainless hlau ntaub thaiv npog

Txhua qhov chaw hauv kev sib cuag nrog dej yog ua los ntawm 304 stainless hlau

8)Thawj thiab peb lub tsheb laij teb

Rau stretching ua ntej preheating, muaj xws li lub cev muaj zog, reducer, peb traction steel rollers thiab kis iav.Kev hloov pauv ceev ceev, oblique iav kis tau tus mob tsis tshua muaj suab nrov, kis tau tus mob.

Lub cev muaj zog kis tau tus mob: turbine turborod

Lub clamp rau cov menyuam yog 120mm nyob rau hauv txoj kab uas hla, nrog kub kub roj hmab txheej thiab mechanical clamping.

9)Tensile qhov cub (kub lub thawv)

Lub thawv cua sov feem ntau ua tiav cov cua sov tensile ntawm PET casting tom qab molding.Cov cua kub ceev yog ceev, uas tuaj yeem ua kom tiav qhov kev taw qhia ncab ntawm PET band.

Lub zog cua sov yog 10.5 kW

Qhov kub thiab txias (℃), + / -1 ℃

Kev tswj qhov kub thiab txias 1

10)Thawj stretching tshuab

Rau stretching tom qab cua sov, muaj li ntawm lub cev muaj zog, reducer, tsib traction steel rollers thiab kis tau tus mob.Kev hloov pauv ceev ceev, oblique iav kis tau tus mob tsis tshua muaj suab nrov, kis tau tus mob.

Cov menyuam rooj yog tag nrho coated nrog nyuaj chromium sandblasting kev kho mob

Lub clamp rau cov menyuam yog 120mm nyob rau hauv txoj kab uas hla, nrog kub kub roj hmab txheej thiab mechanical clamping.

11)Qhov thib ob stretching tshuab

Rau stretching tom qab cua sov, muaj li ntawm lub cev muaj zog, reducer, tsib traction steel rollers thiab kis tau tus mob.Kev hloov pauv ceev ceev tswj oblique iav kis tau tus mob tsis tshua muaj suab nrov, kev sib kis tau yooj yim.

Cov menyuam rooj yog tag nrho coated nrog nyuaj chromium sandblasting kev kho mob

AC zaus hloov pauv tsav lub cev muaj zog yog 11kw

Lub clamp rau cov menyuam yog 120mm nyob rau hauv txoj kab uas hla, nrog kub kub roj hmab txheej thiab mechanical clamping.

12)Paj xovxwm

Cov xovxwm nias rau saum npoo ntawm PET packing siv los txhim kho lub zog sab nraud thiab kev sib txhuam ntawm txoj siv.

Nws muaj cov khoom nram qab no

- Welded steel lub cev tsim

- Carburized steel sab sauv thiab qis yob

-Roller txoj kab uas hla ntawm 150mm, cov menyuam nto kho ntawm HRC55-60.

-Qhov dav dav, 220mm

-Frequency conversion AC lub cev muaj zog yog 5.5KW

- Kab ceev: 140m / min

Siv hydraulic tsav, lub embossing yog smoother thiab yooj yim rau kev khiav lag luam

13) Tighten lub thermal teeb tsa

Tightening kub qhov chaw yog siv rau qhov kub ceev ceev ntawm PET band tom qab tensile, los tiv thaiv kev ntxhov siab sab hauv tshem tawm PET band tom qab tensile orientation thiab stabilize qhov loj ntawm PET band.

13)Lub tank dej txias

Lub tank txias yog siv los tswj qhov ua kom txias thiab crystallinity ntawm cov khoom siv thiab ua kom qhov loj me ntawm cov khoom siv.Ua los ntawm stainless hlau.

Qhov nruab nrab cua txias: dej

Lub dab dej ntev yog 4,000mm

15) Peb lub tsheb laij teb

Rau traction thiab ncab ntawm PET txoj siv tom qab zawm qhov chaw kub thiab txias.Ua los ntawm lub cev muaj zog, reducer, traction roller thiab kis tau tus mob, tag nrho lub thawv kis tau tus mob, tsis muaj deformation, tsis tshua muaj suab nrov kis tau tus mob, kis tau tus mob.

16)PLCDual plex remachine

Rau cov khoom ntim, qhov chaw cia li npaj cov ntim.Nws muaj xws li txais coil, coil core, tsav ntaus ntawv, cov khoom siv hluav taws xob, khib nyiab, hluav taws xob tswj, thiab lwm yam.

Lub PET tau ntim nrog ib daim ntawv txheem cartridge

Kev sib xyaw ntawm dov receiver:

Nacelle hom qauv

Qhov ntsuas txoj kab uas hla ntawm daim ntawv raj yog 406mm

17) Hluav taws xob tswj qhov system

zaus transformer: ABB

Kev ntsuas kub ntsuas: Omron

Contactors: Siemens

Kov npo: Siemens

Main lub cev muaj zog: Siemens