Pp Kev Tsim Kho Template Extruder Tshuab / PP Hollow Sheet Board Siv Formwork Tsev Template Extrusion Kab

Yas hollow pp ntawv extrusion tshuab PP siv tsev board extrusion kab PP hollow bard extrusion tshuab kab

PP siv template extrusion kab yas formwork board ua tshuab

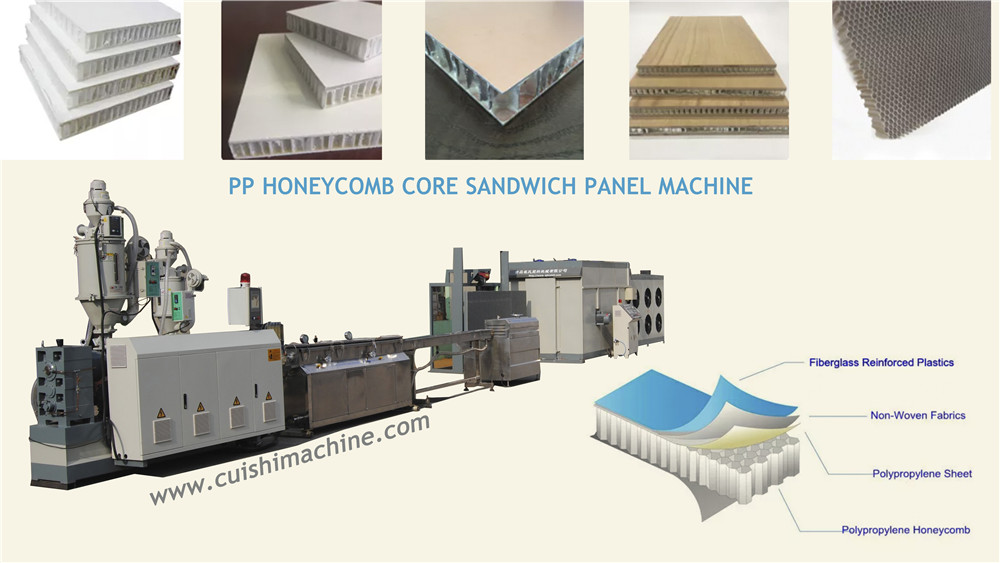

Cov kab ntau lawm tuaj yeem siv PP raw cov ntaub ntawv thiab txais yuav ib lub hau ntswj extruder los tsim peb-txheej hollow nplooj ntawv.Qhov zoo thiab qhov tshwj xeeb ntawm cov phaj tsim ua tau raws li qhov xav tau ntawm lub tuam txhab xav tau.Pp Hollow yas formwork yog ib hom kev txuag hluav taws xob thiab ntsuab ib puag ncig tiv thaiv khoom, pp yas ua ke nrog macromolecule nano-technology.Yas formwork yog ib yam khoom tshiab tom qab ntoo formwork, composite steel formwork, xyoob-ntoo bonding formwork thiab tag nrho-steel loj formwork.Hollow yas formwork yog kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig, thiab tuaj yeem hloov pauv cov tsoos steel formwork, ntoo formwork, square ntoo, Dab tsi ntxiv, nws cov nqi amortization tsawg heev.

PP Yas Siv Lub Rooj Tswjhwm Saib kuj tseem hu ua PP hollow form-work

1) Uas yog ua los ntawm kev hloov kho PP hmoov nrog rau lwm yam additives los ntawm cua sov thiab extruding.

2) Nws muaj lub sijhawm rov siv dua thiab dej pov thawj

3) tuaj yeem hloov cov plywood tsoos.Eco tus phooj ywg thiab yooj yim rau assemble.

4) Plastic Siv Daim Ntawv-ua haujlwm yog ib hom kev tsim cov pob zeb ua vaj tse nrog cov yas rov siv tau.Txoj kev no yuav luag tsis muaj kev txawj ua haujlwm, tau txais txoj haujlwm ua tiav hauv lub sijhawm sau tseg, nrog kev siv nyiaj tsawg tsawg hauv cov txheej txheem.

Cov npe tshuab (PP Hollow Sheet Board Siv Formwork Tsev Template Extrusion Kab Ib Leeg Ntsia Hlau Yas Extruder Machinery)

| Yam khoom | Lub npe | Qty |

| 1.1 | Extruder | ob txheej |

| 1.2 | Pwm | ib set |

| 1.3 | Calibration Unit | ib set |

| 1.4 | Haul-off tshuab | ib set |

| 1.5 | Txias choj | ib set |

| 1.6 | Cuuter | ib set |

PP hollow tsim formwork tshuab

PP lub tsev templates extrusion ntau lawm kab yog ntse tsim los ntawm peb lub tuam txhab kom nqus thiab zom cov txawv teb chaws advanced extrusion technology thiab ywj siab innovation.Lub phaj thickness ntau tuaj yeem ua rau 8-18mm, thiab phaj dav tuaj yeem kho raws li cov neeg siv khoom xav tau ntawm 915mm-1220mm.Nws qhov chaw tsim khoom yog du thiab huv., Me me yuam kev, nrog rau ntsia thawv, npaj, corrosion kuj, nplaim retardant thiab ntau lwm yam zoo.

PP Hollow Lub Tsev Tsim Vaj Tse Board Extrusion Kab PP Hollow Formwork Board Extruder Ua Tshuab

Qhov zoo

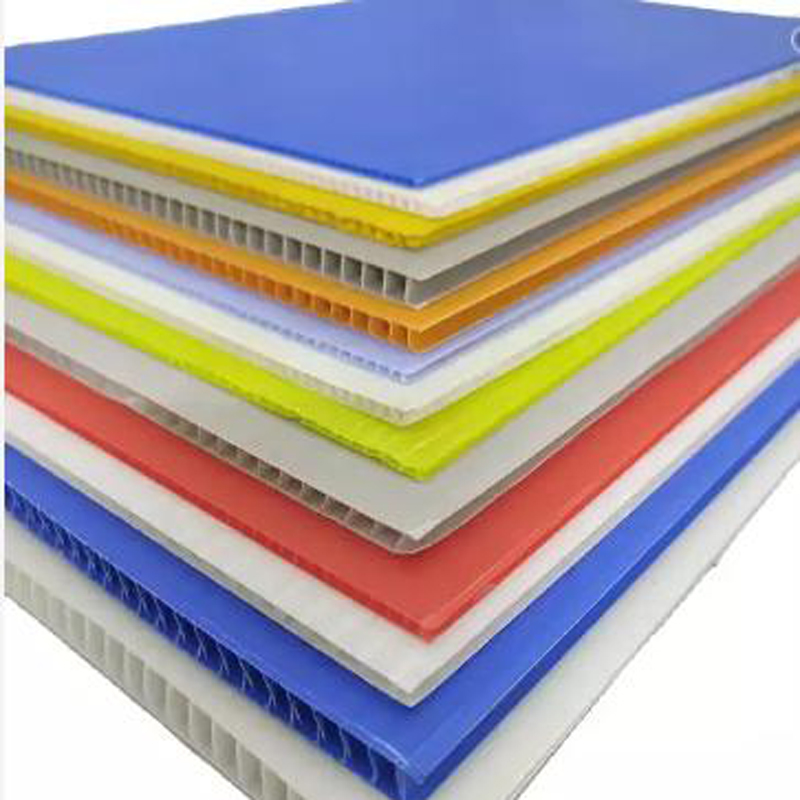

1. Lub teeb yuag, siab zog, siab hardness, cuam tshuam tsis kam, hnav tsis kam.

2. Nto yog du, ci thiab huv si; Concreting thiab forming nyhuv yog zoo rau pp hollow ntawv ua tshuab.

3. Tsis nqus dej noo, tsis muaj deformation, tsis muaj mildew; Lub sij hawm ntev immersion stratification nyob rau hauv dej, tsis muaj npuas, daim ntawv loj stability, tshwj xeeb tshaj yog haum rau underground thiab dampenvironment.

4. Zoo toughness.pp hollow ntawv ua tshuab yuav siv tau raws li cambered tshwj xeeb-puab formwork.

5. Acid thiab alkali tsis kam, corrosion kuj;pp hollow daim ntawv ua tshuab yog tsim nyog rau daim ntawv thov engineering nyob rau hauv ntug dej hiav txwv, kuv, thiab seawall.pp hollow daim ntawv ua tshuab yuav tsum tsis txhob ua tej yam kev kho mob preservative ob leeg nyob rau hauv kev siv thiab khaws cia lub formwork, uas tsis pollute lub pob zeb nto.6. Lub sij hawm rov siv tau rau pp hollow daim ntawv ua tshuab tuaj yeem ncav cuag ntau tshaj 60 zaug, lub neej ua haujlwm ntev.

7. Cov khoom pov tseg tuaj yeem rov ua dua thiab rov ua dua tshiab, ua kom siv tag nrho cov khoom pov tseg.Cov cuab yeej no tuaj yeem txo qhov project nqi piv nrog ntoo formwork thiab xyoob formwork.

8. Kev tiv thaiv ib puag ncig thiab txuag hluav taws xob, tsis muaj kuab paug.Tsis muaj cov pa phem lossis cov pa phem.

9. Demould yooj yim.Tsis tas yuav txhuam tus neeg sawv cev, tsuas yog tapping, tus nqi plywood formwork yuav poob.Txo cov sij hawm ua hauj lwm thiab ua kom lub sij hawm tsim kho kom zoo.

10. Yooj yim rau txheej txheem.Sawing, drilling thiab nailing yog txhua yam muaj.pp hollow ntawv ua tshuab tuaj yeem ua ke vertically thiab horizontally optionally.

11. Yooj yim tshem tawm.Kev tshem tawm yog yooj yim, ceev thiab nyab xeeb, thiab kev txhawb nqa kuj yog ib qho yooj yim rau kev khiav lag luam, ua kom zoo rau lub koom haum kev tsim kho, txhim kho lub sijhawm tsim kho.

Main Technical Specification

| Qauv | SJ 120 | SJ 150 |

| Khoom siv | PP Hloov Cov Khoom Siv | PP Hloov Cov Khoom Siv |

| Cov khoom dav | 915/1220 hli | 915/1220,915 × 2 |

| Khoom thickness | 15-20 hli | 15-20 hli |

| Extruder specification | 120/3575/35 | 150/3590/35 |

| Peev xwm (Max.) | 350-450kg / h | 500-600kg / h |

PP siv lub tsev formwork PP hollow board extrusion

Yas PE PP siv lub tsev formwork extrusion tshuab

PE PP kev tsim qauv template lub tsev formwork ntau lawm kab

PE PP yas formwork board ua tshuab

TXOJ CAI TSHIAB

Kev siv hluav taws xob qis dua

Tus nqi tsim nyog

I. Kev taw qhia tseem ceeb

Nqa cov cuab yeej siv thoob ntiaj teb, nrog rau peb cov kev paub dhau los thiab kev xav tau hauv tsev, cov kab ntau lawm no tau tsim thiab tsim los ntawm peb tus kheej thiab siv los tsim cov ntawv yas, raws li cov neeg siv khoom sib txawv, nws tuaj yeem tsim PVC, PP, PE, PS, ABS, pc, thiab lwm yam.

| qauv | 915/1220 ib | |

| Cov khoom tsim nyog |

| PP / PE |

| Max .dav ntawm cov khoom | mm | 915/1220 ib |

| Thickness ntawm cov khoom | mm | 16/18 |

| Extruder muaj peev xwm | Kg / h | 300-500 |

| Nruab muaj peev xwm (kwv yees) | kw | 350 |

| Dimension (L * W * H) (kwv yees) | m | 35 * 2.5 * 2 |

| Tag nrho qhov hnyav (kwv yees) | t | 10 |