Cov khoom

-

PP Sheet Ua Kab

PP Sheet Ua Kab PP / PE embossed extrudeuse yas ntawv kab maquinaria ua tshuab machinery rau cov ntaub ntawv yas SJ90 SJ120 SJ150 PP / PE daim ntawv ntau lawm kab nrog 0.2-1mm thickness thiab 1220mm ntau lawm dav (nrog 250-500kg / h tso zis) Parameters ntawm ntau lawm kab : Powder: 380v / 3p / 50hz Cov zis: 200 ~ 250kg / h Tag nrho cov dej siv: 8M3 / h Tag nrho cov roj siv: 1M3 / h Tag nrho cov hwj huam noj: 175KW Tag nrho cov khoom siv hluav taws xob: 220KW Pem teb qhov chaw: 20000MM(L) X 2500MM(W ) X 3200M... -

pp hollow sheet ntau lawm kab / pc ntawv ntau lawm kab

PP PE PC Hollow Sheet Extrusion Kab 1.STS120/3 ib leeg ntsia hlau extruder 1 teeb STS45/30 ib leeg ntsia hlau extruder 1 teeb 3.T-tuag 2sets 4.Hydraulic screen exchanger 1 teeb 5.Metering twj tso kua mis 1 set 6.calibration unit 1 set 7.thawj coj-tawm chav tsev 1 teeb 8.Sab trimming tshuab 1 teeb 9.anneal cub 1 set 10 . thib ob haul-off unit 1 set 11. transverse cutter 1 set 12 . protective film covering unit 1 set 13. transmission unit 1 set 14 1.. -

Txhaj tshuab thiab pwm

High Precision Servo Txhaj Molding Tshuab tsis ITEM UNIT DATA Txhaj Unit Screw Diameter mm 70 75 80 Screw L/D Ratio L/D 23 21./5 20.2 Txhaj Volume cm3 1347 1546 1759 Shot Weight g 101826 Injection 75 101826 Clamping Unit Clamping Force kN 3900 Qhib Stroke mm 710 Pwm Thickness (Min-Max) ... -

PET daim ntawv extrusion ntau lawm kab

Kev kub ceev PE, PP, PS, ABS, PMMA, PET daim ntawv tsim khoom siv ntawv extrusion ntau lawm kab

Qhov kev qhia tshwj xeeb no suav nrog kev tsim cov tshuab ntawm PET daim ntawv ntau lawm, suav nrog kev tsim khoom noj, extruder, yaj kab (nrog rau kev pom thiab ntsuas), lub taub hau tuag, casting, traction thiab winding, thiab lwm yam. -

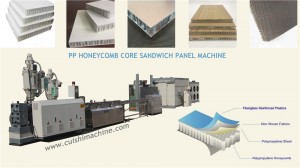

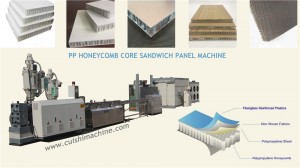

pp pc honeycomb cellular board extrusion tshuab

yas honeycomb vaj huam sib luag ntau lawm kab hu ua PP honeycomb board ua machinery pp honeycomb daim ntawv tshuab Cov yeeb nkab txoj kab uas hla 8 hli -12 hli Cell Diameter Yas PP Honeycomb Core With Non Woven Fabric thiab Barrier Film for Lamination Sandwich Panel Durable Customized PP Honeycomb Core for Waterjet Bricks A high-density cut-resistant PP honeycomb core dej dav hlau txiav txaj tsim nrog lub zog siab, cov khoom no yuav ua rau kom muaj kev ruaj khov.PP honeycomb tub ntxhais dej dav hlau txiav txaj yog m ... -

PE PP PC yeeb nkab raj extrusion tshuab

PE Yeeb Nkab Extrusion Tshuab feem ntau yog siv los ua cov kav dej ua liaj ua teb, cov kav dej, cov kav dej, cov kav dej, cov kav dej, cov kav dej cable thiab lwm yam.

-

PVC yas yeeb nkab ua tshuab

PVC yeeb nkab kab yog tsuas yog siv nyob rau hauv zus tau tej cov Agricultural dej mov & dej paug system, architectural dej mov & tawm system, xaim nteg system, thiab lwm yam hom phiaj.

-

PVC Qhov rai / Qhov Rooj Extrusion tshuab

tsim Lub Tsev Muaj PVC Qhov rai / Qhov Rooj Kab Hlauv Phab Ntsa Extrusion Profiles

Nws yog qhov nruj / tawv UPVC profile (rigid PVC) rau viav vias qhov rooj, chav nyob qhov rooj, lub qhov rooj tig, lub qhov rooj chav pw, qhov rooj da dej, qhov rooj txee, lub qhov rooj tub yees, lub qhov rooj tub yees, lub qhov rooj tub yees, lub qhov rooj fridge, txhua yam ntawm qhov rais, qee yam ntawm tsev neeg, kev tsim kho thiab lwm yam kev lag luam siv.

Professional upvc profile tshuab chaw tsim tshuaj paus

upvc qhov rais & qhov rooj tshuab manufacturers -

PET PP pluaj packing daim kab xev extrusion kab

1. Kev teeb tsa lub zog: 120kw, kev siv hluav taws xob tiag tiag 70% ntawm nws.

2. Khoom siv: PET flakes

3. Tshuab Dimension: 28 * 4 * 3.5m -

WPC PE PVC ntoo hmoov Profile Extrusion Kab

PVC / WPC ua tshuab tuaj yeem tsim txhua yam profile, piv txwv li, qhov rais, qhov rooj thiab qhov rooj ncej, pallet, cladding ntawm sab nraum zoov phab ntsa, chaw ua si sab nraum zoov, pem teb thiab lwm yam. Cov ntaub ntawv tso tawm yog Wood Plastic Composite (WPC) lossis yas UPVC.

-

Yas PP PE PVC profile tshuab PVC WPC profile extrusion kab

PVC WPC profile extrusion kab yog tsim los ua hollow lossis khoom PVC WPC foaming profiles.Cov profiles no muaj qhov zoo ntawm fireproof, waterproof, anticaustic, noo noo pov thawj, npauj pov thawj, mildew pov thawj, non-toxic thiab environmentally friendly.Cov profiles yog dav siv nyob rau hauv kev kho kom zoo nkauj sab hauv, rooj tog zaum, xws li lub qhov rooj ncej, skirting,

Peb ua kev tshawb fawb txuas ntxiv thiab kev tsim kho tshiab rau cov txheej txheem extrusion customized raws li qhov xav tau sib txawv -

100-3000kg / h Vertical PVC Kub Thiab Txias Sib Nqus Tshuab

1.Blending Master Batch nrog cov nkauj xwb granules.

2.Mixing Pigments lossis Pigment Paste nrog granules lossis polymers hmoov.

3.Blending Pigment thiab Fillers additives.