PVC Ua Npuas Ncauj Board Extrusion Tshuab

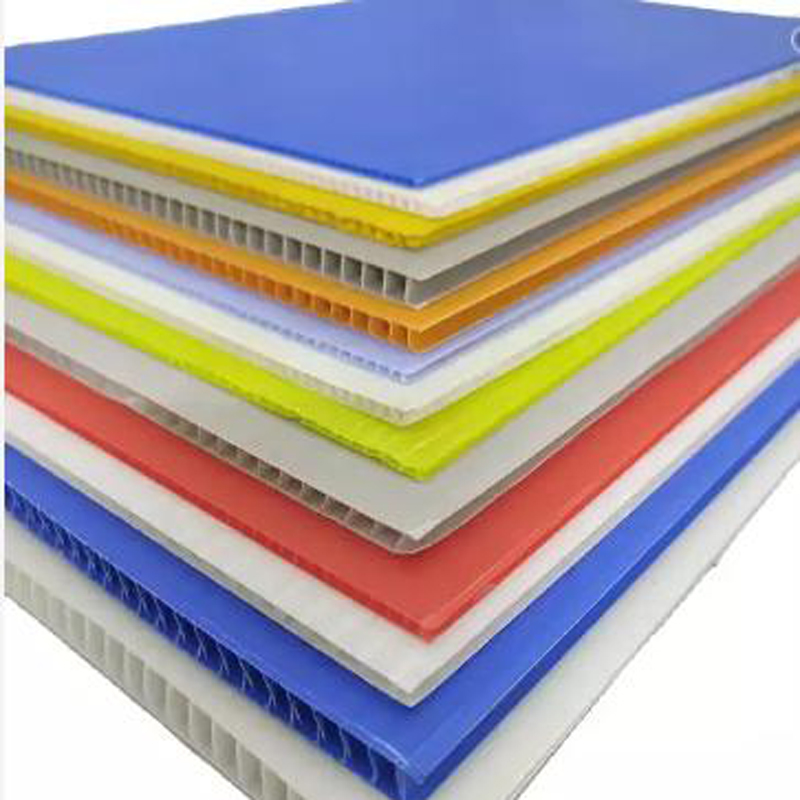

Product Description

Lub ntsiab feature ntawm Yas PVC WPC ntoo yas composite ua npuas ncauj board extrusion kab / rooj board Ua Tshuab / extruder:

- Zaus converter: SIEMENS;

- 2.Pull set Siemens hluav taws xob qhov chaw: Main lub cev muaj zog / AC contactor / thermal overload relay / Circuit Court breaker (xws li qhov loj Circuit Court breaker ntawm tag nrho cov kab) / tawm tswv yim;

- 3.PLC: SIEMENS

- 4.Temperature controller: OMRON Nyiv

- 5.Relay / mus txawv tebchaws: Schneider Fabkis

- 6.Twin-Screw: nto moo hom los ntawm Zhoushan, Suav teb

- 7.Mould: Tuam Tshoj nto moo hom xws li: JC Times / EkO / Weilei

| WPC PVC Celuka ua npuas ncauj board cov ntaub ntawv yooj yim: | |

| Cov khoom tseem ceeb | PVC / CaCo3 / additives |

| Ua tiav board loj | 1220-2050mm (dav) * 2440mm (ntev-adjustbable) |

| Ua tiav board thickness ntau yam | 3-25mm / 3-30mm / 3-40mm |

| Max extruder muaj peev xwm | 400kgs/h/600kgs/h/800kgs/h/1000kgs/h |

| Board nto kho | Embossing / hloov luam / lamination / uv txheej / CNC engraving |

| Extruder pwm | SYSJ-80/156 | SYSJ-80/173 | SYSJ-92/188 | |

| Tso zis muaj peev xwm | kgs/h | 350 | 550 | 650 |

| Output thickness | mm | 3-25 | 3-30 | 3-30 |

| Tshuab List | |||

| Tsis muaj. | Lub npe | Qty. | Lus ceeb toom |

| 1 | Ntsia hlau loader rau extruder | 1 | |

| 2 | SJZ 80/156 conical ntxaib ntsia hlau extruder | 1 | |

| 3 | Extrusion pwm unit | 1 | 1220 * 2440 hli |

| 4 | Nqus calibration Table | 1 | |

| 5 | Cua txias bracket | 1 | |

| 6 | Tshem tawm unit | 1 | |

| 7 | Ntug txiav tshuab | 1 | |

| 8 | Taug qab cutter | 1 | |

| 9 | Tsis siv neeg hloov tshuab | 1 | |

| 10 | Plua plav khoom siv | 1 | |

| 11 | Pwm kub tswj | 1 | |

| Kev Pabcuam Tshuab | |||

| 12 | SRL-Z Series Tov Khoom | 1 | Muaj peev xwm: 450-550kg / h |

| 13 | Ntsia Hlau Loader rau Tov Khoom | 1 | |

| 14 | Crusher | 1 | Lub Zog: 11kw, 22kw, 30kw |

| 15 | Pulverizer | 1 | Lub Zog: 45kw, 55kw, 75kw |

Daim ntawv teev cov tshuab thiab qhov zoo

Cov kab ntau lawm & Pab cov cav tov:

| Ntu a: Yas WPC PVC ntoo yas sib xyaw ua npuas ncauj board extrusion kab / qhov rooj board ua tshuab | ||||

| TSIS MUAJ. | Lub npe tshuab | Hom | Qty. | Nco tseg |

| 1 | Conical ntxaib ntsia hlau extruder | SJSZ80/156 SJSZ92/188 | 1set ib | nrog caij nplooj ntoos hlav loader |

| 2 | Hluav taws xob tswj qhov system | 1set ib | Siemens hluav taws xob qhov chaw | |

| 3 | T-pwm | 1set ib | JC Times/Eko/Weilei | |

| 4 | Calibration unit | 1set ib | Loj: 1500 * 600 * 100mm | |

| 5 | Cua txias bracket | 1set ib | 5000mm (ntev) * 1500mm (dav) | |

| 6 | Haul-off device | 1set ib | 8pairs/10pairs/12pairs | |

| 7 | Shearing unit nyob rau hauv ntev thiab dav | 1set ib | ||

| 8 | Plua plav collector | 1set ib | ||

| 9 | Stacker | 1set ib | 2500mm * 1750mm | |

| TSIS MUAJ. | Lub npe tshuab | Qhov zoo ntawm lub tshuab |

| 1 | Automatic feed loader | Tsis siv neeg puv |

| 2 | Conical Twin Ntsia Hlau Extruder | Inovince servo lub cev muaj zog, nto moo hom gearbox thiab tag nrho ntawm SIEMENS hluav taws xob tswj qhov system,30% Txuag hluav taws xob, ruaj khov khiav, ua haujlwm ntev

|

| 3 | T- tuag | Tsim los ntawm peb tus kheej nrog ntau tshaj 23 xyoo kev tsim khoom Extrusion thiab calibration pwm Technical parameters: a.Unique tuag qauv rau cov khoom hollow siv cov tub ntxhais molding optimized ntws txoj kev los ntawm lub computer simulation kom zoo ib yam thiab ruaj khov txaus. b.Independent air flow control system kom ceev nrooj sib npaug ntawm airflow nyob rau hauv ib lub sij hawm luv luv kom tau ib tug ruaj khov ntau lawm. c.Fine polishing ntawm kab noj hniav, di ncauj thiab ntws channel. |

| 4 | Calibrator | 100mm thickness iav nto calibrator |

| 5 | Txias Bracket | 9 pcs stainless hlau rollers |

| 6 | Tshem tawm lub tshuab | 8-12 khub roj hmab nto chais |

| 7 | Stacker nrog tsis siv neeg robert board nqa | |

| Auxiliary machines (yeem) | ||

| 1 | Crusher | Rau recycling unqualified board |

| 2 | Grinder | Rau recycling unqualified board |

| 3 | Kev kub ceev / cua txias tov khoom | Rau kev sib tov raw khoom |

| 4 | Chiller | Txhawm rau muab dej txias |

Number of set plates: 4 khub

Teem phaj dav: 600mm

Phaj Thickness: 90mm

Qhov ntev ntawm qhov chaw phaj: 1500mm

Cov txheej txheem kev kho mob: quenching thiab tempering + nyuaj chromium plating + polishing

Txias ntawm qhov chaw phaj: dej txias, tsim tshwj xeeb tsim cov channel ntws, ua kom txias zoo

Lifting ntawm qhov chaw phaj: hydraulic tswj, cais lifting tswj

Kev kho hom ntawm sab sauv formwork: fine adjustment ntsia hlau

Kev kho cov txheej txheem ntawm nqa phau ntawv qhia tom qab kho kab ke: quenching thiab tempering + nyuaj chromium plating + polishing

Pem hauv ntej thiab nram qab taug kev hom ntawm hluav taws xob platform

Lub cev muaj zog: 0.37kw

Daim ntawv Reducer nmrv-40 / 75-500-0.37

Zuag qhia tag nrho qhov siab hloov hom ntawm platform: phau ntawv hloov

Platform zuag qhia tag nrho tswj ywj siab tswj vaj huam sib luag

Kev tswj vaj huam sib luag yog tsim los ntawm qhov taw qhia lub zog, lub cav tseem ceeb rau-tawm mus, khawm nres thaum muaj xwm ceev, tachometer, zoo hloov khawm, v

| Pvc Ua Npuas Ncauj Board Physical Properties | ||

| Cov khoom kuaj | Chav tsev | Kev Xeem Xeem |

| Qhov ntom | g/cm3 | 0.35-1.0 Nws |

| Tensile zog | Mpa | 12-20 |

| Bending Intensity | Mpa | 12-18 |

| Khoov elasticity Modulus | Mpa | 800-900 Nws |

| Impacting Intensity | KJ/m2 | 8-15 |

| Breakage Elongation | % | 15-20 |

| Ntug hardness D. | D | 45-50 |

| Kev nqus dej | % | ≤1.5 |

| Vicar Softening Point | ºC | 73-76 : kuv |

| Hluav taws kub tsis kam | Self-Extinguishing Tsawg dua 5 vib nas this | |