QINGDAO CUISHI PLASTIC MACHINERY CO., LTD

Granulator

Zoo siab tso zis kub yas pellet/pipe/cubeextruder tshuab yas recycling khoom

SJ series ib leeg ntsia hlau extruder yas tshuab feem ntau siv rau extrude PP, PE, PET, PVC, ABS, PS, PA ect khoom. .Nws muaj cov pwm sib txawv thiab cov cuab yeej pabcuam, nws tuaj yeem tsim cov yeeb nkab yas, ntawv, pawg thawj coj saib, granules thiab lwm yam .Nws muaj cov yam ntxwv ntawm cov txheej txheem yooj yim, cov zis siab, ruaj khov extrusion siab, thiab tus nqi qis.

| Qhov project:DJ85 ib o ntsia hlau pelletizing kab | |

| Raw khoom & formula | PE films |

| Cov khoom kawg | PE granules |

| Tso zis muaj peev xwm | 120-200kg / h , nyob ntawm cov khoom tus yam ntxwv. |

| Central qhov siab | 1,14m ib |

pp pe pelletizing kab yas recycling granulating tshuab pov tseg yas granules ua tshuab

Parameters(CSSeries Ob Chav Theem Compactor-Granulator):

| Model (ob theem) | CS85-100 UAS | CS100-120 | PIB 130-150 | PIB 160-180 | PIB 180-200 |

| Ntsia Hlau Diameter (mm) | 85 | 100 | 130 | 160 | 180 |

| L/D | 25-42 : kuv | 25-42 : kuv | 25-33 : kuv | 25-33 : kuv | 25-33 : kuv |

| Peev xwm (kg / h) | 150-200 | 300-350 | 500 | 600-700 Nws | 800-1000 |

Daim ntawv thov:

PE, PP zaj duab xis, Silk, Flakes (≤0.5mm), Hnab, thiab lwm yam.

Nco ntsoov, peb CS series compactor granulator tuaj yeem rub tawm txoj kev txiav, lossis dej nplhaib txiav txoj kev xaiv

Muaj xws li:

Siv conveyor (hlau ntes) → Compactor → Main extruder (nqus degassing system) → Hydraulic screen changer → Sub- extruder →

Hydraulic screen changer → Dej nplhaib txiav system → Dewatering tshuab → Cua tshuab → Cia hopper → tswj txee

- Cov ntaub ntawv dav dav

1.1Pem teb chaw

Kev tsim kho yooj yim, kev ua haujlwm hauv av, kev ua haujlwm phab ntsa yuav tsum tau ua tiav zoo los ntawm Tus Neeg Yuav kom txais cov kab pelletizing no.

Cov neeg yuav khoom yuav tsum muab cov crane, forklift lossis lwm yam khoom nqa nqa, cov khoom siv thiab cov cuab yeej.

Thaj Chaw: yuav tsum tau tsim raws li kab layout.

1.2Fais fab mov

Nruab lub zog:106KW (kev siv lub zog siv tau kwv yees li 70%)

Fais fab mov:

Cov khoom siv hluav taws xob: 3 * 380V + N + PE;

Voltage kam rau ua: + 10% / -5%;

Tswj voltage: 24VDC + 220VAC;

Zaus: 50Hz + -2%

Hlau / cables:

- Hlau / cable los ntawm lub hwj chim mov mus rau tswj txee (muab los ntawm Buyer).

- Txhua qhov hluav taws xob cables los ntawm kev tswj txee rau txhua lub tshuab (muab los ntawm Tus Neeg Yuav Khoom).

1.3Kev muab dej

Kev siv:0.6T / h (dej rov siv dua)

Cov dej txias:

Tsis muaj yaj lossis tshem tawm cov zaub mov xws li phosphor, sulfur, hlau, thiab lwm yam.

Inflow kub T1: max.15 ℃

Kev khiav hauj lwm kub T2: T2 = T1 + 5 ℃

Inflow siab, min: 2.5bar

Hardness: 5-8ºdH;

Reflux: tsis muaj zog

Hose dej:

Los ntawm kev muab dej rau txhua lub tshuab (muab los ntawm Tus Neeg Yuav).

1.4Compressed cua:0,6m ua3/min, 0.4 ~ 0.7Mpa

1.5Cov neeg ua haujlwm ua haujlwm

2-3 Cov neeg

1.6Lubrication roj

Tau txais hauv khw hauv zos ntawm kev pom zoo ntawm Tus Neeg Muag Khoom (muab los ntawm Tus Neeg Yuav Khoom).

- Cov ntsiab lus lag luam

2. 1Machine lis & Nqe

| Tsis muaj. | Ntaus lub npe | Qauv | Qty (set) |

| 1 | Siv conveyor |

| 1 |

| 2 | Compactor |

| 1 |

| 3 | DJ85/33single ntsia hlau extruder | DJ85/33 ib | 1 |

| 4 | Phaj hom Hydraulic screen changer160 |

| 1 |

| 5 | Dej nplhaib txiav system |

| 1 |

| 6 | Vibrating screen dewatering tshuab |

| 1 |

| 7 | Silo |

| 1 |

| 8 | Hluav taws xobtxee |

| 1 |

2.2Cov nqe lus them nqi

- 40% raws li tso nyiaj los ntawm T / T.

- 60% raws li qhov nyiaj tshuav los ntawm T / T ua ntej xa khoom thiab tom qab kuaj xyuas.

2.3Lub sij hawm xa tuaj

Hauv 50 hnub ua haujlwm txij li hnub tau txais qhov tso nyiaj.

2.4Ntim

Yas zaj duab xis.

2.5Warranty

13 lub hlis rau cov khoom siv kho tshuab txij li hnub ntawm daim nqi ntawm kev thauj khoom.Peb lub hlis lav rau cov khoom siv hluav taws xob yog tias cov khoom siv hluav taws xob hauv Lub Hoobkas tsis ruaj khov.

cuishi yuav tsub tus nqi buyer tus nqi ntawm cov khoom seem tom qab cov khoom tawm ntawm warranty thiab muab cov kev qhia mus sij hawm ntev.

2.6Installation & Commissioning

- Cov neeg yuav khoom yuav tsum tau npaj rau kev teeb tsa thaum cov cuab yeej tuaj txog, xws li cov khoom siv hluav taws xob, dej, kev ua haujlwm thiab cranes, thiab lwm yam.

- cuishi yuav npaj rau daim ntawv thov vixaj rau cov engineers, leej twg yuav mus rau Buyer lub Hoobkas rau commissioning txoj hauj lwm.

- Tus neeg yuav khoom yuav tsum tau them daim pib caij dav hlau mus ncig rau cov kws ua haujlwm yog tias daim ntawv thov vixaj raug pom zoo, thiab them cov nuj nqis tsim tawm xws li vixaj kev cai, pluas noj, kev pab thiab nyiaj pub dawb ntawm USD100 ib hnub rau txhua tus engineer.

2.7Kev siv tau

- 60 hnub txij li hnub hais.

3.Technical specification

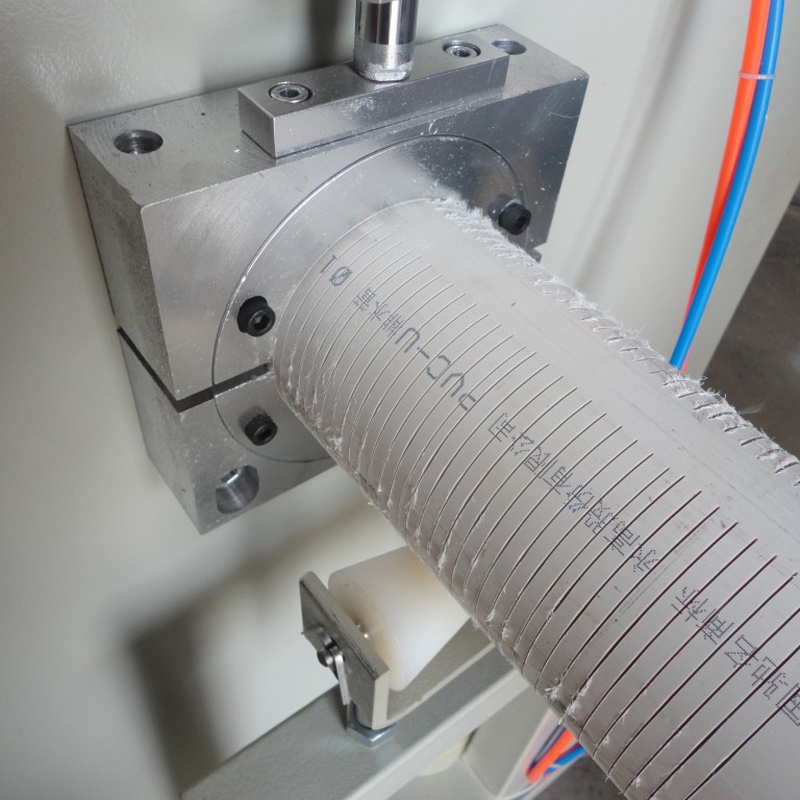

3.1DJ85 Ib leeg ntsia hlau extruder

5Dej nplhaib txiav system

hniav thiab cov tuag, thiab lub siab ntawm riam yog cia li hloov mus rau xyuas kom meej lub uniform txiav quab yuam ntawm riam. Pib lub kaw lus nrog ib tus yuam sij kom ua haujlwm ntawm tag nrho cov system ntau dua yooj yim; Kab rov tav tuag ntsej muag cutter Lub cev muaj zog: 2.2kw Lub zog ntawm lub twj tso kua mis: 2.2kw Lub cutter yog zaus tswj los ntawm inverter | |

| 6 | Vibrating screen dewatering tshuab |

Advanced dewatering vibrating npo ua ke nrog kab rov tav centrifugal ziab tuaj yeem ua tiav kev ua haujlwm kom qhuav thiab qis zog.cuishi txais kev tsim qauv kaw thiab nruab nrog lub npog tsis muaj suab nrov, uas muaj suab nrov tsawg thiab yog tus neeg siv ntau dua.

Lub cev muaj zog: 0.25kw * 2. Yam khoom uas tiv tauj dej: SUS304. Sib dhos sieves: tsis welded.Txhim kho thiab kho los ntawm screws, kom yooj yim hloov tshiab sieves yav tom ntej. Springs yog ib puag ncig nrog roj hmab, tiv thaiv los ntawm qhov sib txawv loj loj los ntawm lub caij nplooj ntoo hlav. Tsim tshwj xeeb los tiv thaiv me me impurities poob rau hauv dej twj.

Lub cev muaj zog: 3kw. Rotary ceev: 1460 rpm Yam khoom uas hu rau dej thiab granules: SUS304. | |

| 7 | Silo |

| Muaj peev xwm ua tau: 700LCov khoom ntawm ib feem nyob rau hauv kev sib cuag nrog cov khoom Stainless hlau | |

| 8 | Hluav taws xobtxee |

Lub kaw lus tswj tau txais Siemensctswj, thiab yog nruab nrog industrial-qib kov ua haujlwm screen (yeem khoom)

Raws li cov txheej txheem kev teeb tsa thiab cov txheej txheem tuav cov khoom yuav tsum tau ua, qhov txuas cuishi system paub txog ib qho tseem ceeb pib, yog li zam kev ua yuam kev hauv phau ntawv pib txheej txheem.

Nrog kev pab los ntawm ib chav tsev tshwj xeeb, cuishi system tuaj yeem paub txog ib qho tseem ceeb kaw ntawm tag nrho cov system module kom tsis txhob muaj cov khoom puas tsuaj los ntawm kev ua haujlwm tsis raug thaum lub sijhawm kaw.

cuishi yog nruab nrog lub luag haujlwm nres thaum muaj xwm txheej ceev, uas yog siv los ua qhov xwm txheej ceev rau qhov tsis txaus ntseeg thaum lub sijhawm ua haujlwm ntawm lub tshuab, kaw tag nrho cov txheej txheem kom sai thiab ceev kom tsis txhob muaj xwm txheej thib ob thiab raug mob.

Cov cuab yeej tiv thaiv lub neej Lub cuishi system tag nrho coj mus rau hauv tus account qhov teeb meem kev nyab xeeb ntawm cov khoom siv thaum lub sijhawm ua haujlwm.Txhua qhov chaw khiav hauj lwm thiab kev sib hloov txoj hauj lwm yog nruab nrog cov hluav taws xob kev nyab xeeb hloov kom ntseeg tau tias muaj kev nyab xeeb ntawm cov khoom siv thaum lub sijhawm ua haujlwm thiab zam kom tsis txhob muaj kev phom sij thaum lub sijhawm ua haujlwm ntawm cov cuab yeej ua rau muaj kev puas tsuaj rau cov neeg siv khoom.

Nrog kev pab los ntawm kev tswj qhov kub thiab txias thiab lub hom phiaj optimization tsim ntawm cov txheej txheem plasticizing, lub cuishi system tuaj yeem ua kom ntseeg tau thiab ruaj khov ntawm qhov kawg pelleting zoo.

Nrog kev pab los ntawm kev tswj hwm lub hauv paus ntsiab lus thiab kev paub txog kev ua tau zoo ntawm cov khoom siv rov ua dua tshiab, cuishi system tuaj yeem xyuas kom meej tias cov khoom siv pov tseg ua tiav tau qhov zoo tshaj plaws preheating thiab compaction xeev nyob rau hauv lub compaction chamber, thiab tuaj yeem zam cov khoom siv rov qab los ntawm cov yas. .Overheating los yog degradation nyob rau hauv lub warehouse. Contactor: Schneider Relay: CHNT General hloov: CHNT Circuit Breaker: CHNT Lus Cim: Cov neeg siv khoom xav tau muab cov xaim los ntawm lub txee tswj rau txhua lub tshuab.

|

3.2 Khoom seems: FOC

Mechanical ib feem

| No | Lub npe | Chav tsev | Qty |

| 1 | Kub txiav hniav | daim | 2 |

| 2 | Ntsia hlau tshem tawm cov cuab yeej | teeb | 1 |

| 3 | Asbestos hnab looj tes | khub | 1 |

| 4 | Input thiab output ncej roj foob | teeb | 1 |

| 5 | Nqus O-ring | daim | 2 |

Hluav taws xob qhov chaw

| No | Lub npe | Chav tsev | Qty |

| 1 | AC contactor | daim | 1 |

| 2 | Khawm | daim | 2 |

| 3 | Kub lub rooj | daim | 1 |

| 4 | Thermocouple | daim | 2 |

4.Kev tshuaj xyuas ua ntej xa khoom

Tus Neeg Muag Khoom yog lub luag haujlwm rau kev teeb tsa kev sim ua ntej xa khoom.