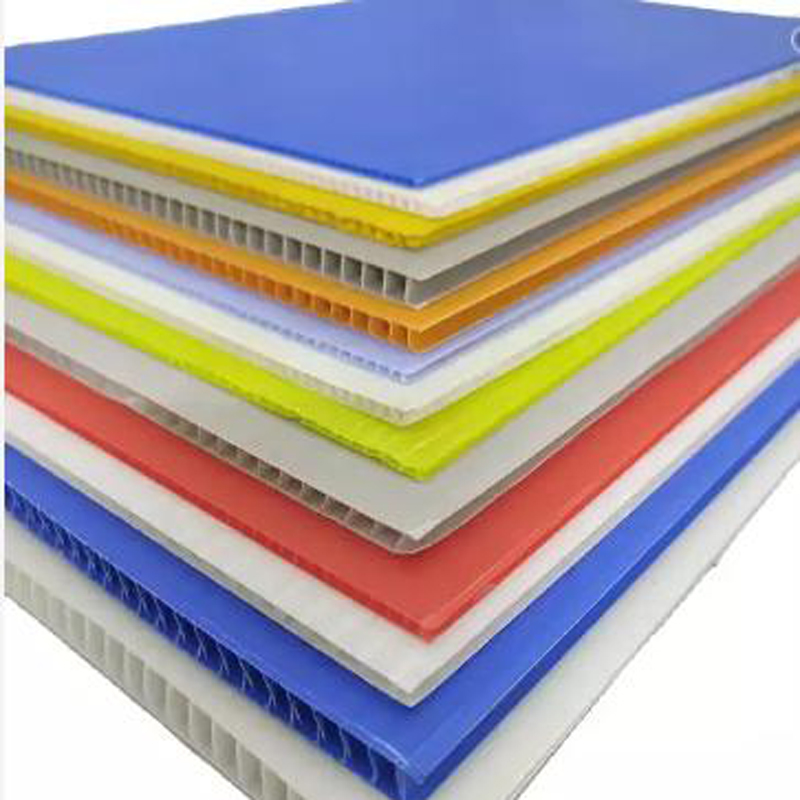

PET daim ntawv ntau lawm kab

PET daim ntawv kab Ib txheej nrog 0.3-1mm, dav 800mmh

PET daim ntawv ntau lawm kab yog ib qho ntawm cov kab ntau lawm nrog cov thev naus laus zis siab, cov cuab yeej paub tab thiab cov khoom siv ruaj khov hauv peb lub tuam txhab.Calender, txias traction bracket, ob chav chaw nres tsheb winding, thiab lwm yam.

Cov khoom siv yog compact hauv cov qauv thiab superior hauv kev ua haujlwm.Cov ntsia hlau thiab lub thoob yog optimally tsim.

Lub tshuab tag nrho muaj qhov zoo ntawm cov yas yas, ruaj khov extrusion, siab tso zis thiab lub neej ua haujlwm ntev.

Cov cuab yeej ua kom zoo nkauj thiab calendering ua rau daim ntawv zoo li zoo los ntawm nws qhov kev hloov kho zoo.

Cov ntawv PET uas tsim los ntawm cov cuab yeej no tuaj yeem ua rau thermoformed rau hauv ntau cov khoom ntim, muaj cov khoom siv roj zoo, tsis muaj lwm yam khoom ntxiv, yog huv si thiab huv si, zoo toughness thiab extensibility, thiab zoo heev recyclability., tuaj yeem siv dav hauv cov khoom siv hluav taws xob, cov khoom ua si, khoom noj, tshuaj thiab lwm yam ntim thiab kev lag luam luam ntawv loj heev.

Piv nrog cov cuab yeej zoo sib xws hauv tsev, qhov kev nkag siab yog ntau dua 30% siab dua.Cov kab ntau lawm no tseem tuaj yeem siv rau PS, PP, PE thiab lwm yam khoom siv.

Cov tsiaj ntawv kab nrog rau kev pub mis, extruders, yaj kab (xws li pom, metering) tuag, casting nplooj ntawv, traction thiab winding.

Tsim cov ntaub ntawv yooj yim

Cov yam ntxwv ntawm PET daim ntawv ntau lawm kab khoom siv:

1. Cov ntsia hlau tshwj xeeb tsim kom muaj peev xwm ntau lawm thaum ua kom muaj kev sib xyaw thiab muaj peev xwm plasticizing siab, nrog lub peev xwm ntau lawm ntawm 1.5 tons / teev.

2. Kev tsim ob-thooj ntawm lub puab-thaiv hanger-hom tuag lub taub hau tuaj yeem siv los kho qhov dav ntawm cov khoom hauv online ntawm qhov chaw ua kom ntseeg tau tias cov tuab tuab.

3.Qhov kev tswj xyuas lub sijhawm tiag tiag ntawm cov khoom siv hluav taws xob tuaj yeem ua kom muaj kev ruaj ntseg thiab kev ntseeg siab ntawm qhov system.

4. Peb-roller calender nrog kauv sab hauv ntws channel, sab hauv phab ntsa yog CNC lub tsheb-ntxuav, thiab qhov kub thiab txias yog guaranteed tswj nyob rau hauv ± 1 ° C.

5. Siv Siemens PLC, tag nrho cov kab ke tswj tau tswj tsis tau phau ntawv hloov.

6. Tsis siv neeg ob chav nres tsheb winder, tswj los ntawm servo lub cev muaj zog, ceev ceev 60m / min

7. Cov ntaub ntawv raw: polyester ntshiab raw cov ntaub ntawv, los yog polyester recycled cov ntaub ntawv:

PET hom: raw khoom hlais,

φ 3mm * L3mm, Qhov ceev: 700 ~ 880kg / m3

2.3 polyester recycling khoom hom:

PET lub raj mis, PET nti recycling khoom, txoj kab uas hla 3mm- inch 6mm, Thickness ≥ 0.15mm, Intrinsic viscosity: 0.5 ~ 0.65g / dl

Cov dej noo: ≤ 0.5 ‰

8. Cov yam ntxwv ntawm cov khoom: Thickness: 0.3-1.0mm

Structure: ib txheej, txheej txheej: 100%

Dav: 800mm (tom qab trimming)

Winding txoj kab uas hla (siab tshaj): 600mm (mechanical tsim txwv)

ntau lawm ceev: 3 ~ 30m / min

Extrusion peev: Tsim muaj peev xwm: 450kg / h

Technical specification

Part 1: Twin ntsia hlau host/extruder 75/132kw 40: 1

Qhuav thiab sib tov ntawm raw cov ntaub ntawv 2m3 qhuav mixing hopper

Feeding system: Kauv feeding

feeding system: Volumetric metering pub

Cooling system: Cua txias

Forced lub tshuab nqus tsev twj tso kua mis: Lub nplhaib dej lub tshuab nqus tsev twj tso kua mis + buffer tank

Txo gearbox: High torque txo gearbox NSK bearing

Cov kab ntau lawm steel thav duab platform: suav nrog kev hloov pauv kev txhawb nqa, yaj twj tso kua mis thiab tuag hanger

Part 2: screen changer, metering twj tso kua mis thiab T puab pwm

Ntu 3: peb lub calender nrog txoj kab uas hla 400 500 500mm

Kev ywj pheej tsav calender tuaj yeem hloov kho ntawm pem hauv ntej mus rau sab nraub qaum, nce thiab nqis

Khoom siv: Aluminium idler

Traction ntawm ib tug roj hmab cov menyuam thiab ib tug hlau cov menyuam 160mm lub cev muaj zog 1.5kw

Tsis siv neeg synchronization nrog nro hloov

ABB zaus converter

Italian Jefferson tshem tawm sensor

Ntu 4 Ntu 4: tsheb laij teb / daim ntawv tshem tawm 1 txheej txiav ntug chav tsev: nrog riam 2 pcs

Ntu 5: ob txoj haujlwm winder 1 teeb

Ntu 6 hluav taws xob qhov chaw

Nws suav nrog kev tswj qhov kub thiab txias thiab txais cov khoom siv hauv lub xeev relay.Tsav tswj ib feem, hloov pauv zaus lub cev muaj zog, Siemens PLC, Taiwan vellon kov npo.Kev tswj ceev thiab siab kaw-voj tswj tau paub txog cov khoom sib kis ntawm extruder.Zoo meej tswb, kev tiv thaiv, thiab cov ntaub ntawv keeb kwm ntawm txhua qib los pab txhawb kev tsim khoom thiab tswj.

Ⅲ.Cov lus piav qhia ntxaws ntawm cov kab ntau lawm

Ntu I: ntxaib ntsia hlau extruder

1. raw khoom sib tov thiab pub system 1 teeb

Nruab nrog qhuav sib tov hopper, nrog ib tug ntim ntawm 2 cubic meters

Caij nplooj ntoos hlav coil pub.Stainless steel txheej txheej, caij nplooj ntoos hlav ua los ntawm cov hlau zoo caij nplooj ntoos hlav.Cov khoom siv tau tuaj yeem rov ua dua los ntawm cov khoom siv qib sensor.

1.0) ntsia hlau metering feeder

Nruab ntawm thawj chim 1 teeb

Screw metering noj, lub cev muaj zog: 1.5kw

Cov kev tswj ceev hom yog tswj los ntawm AC zaus converter

2.0) ntxaib ntsia hlau extruder 1 teeb

2.1) Ib Tsav Tsav Tsheb: Txais yuav hloov lub cev muaj zog, nrog lub zog ntawm 132kw;Tus tswv xeev: Xaiv qhov hloov pauv zaus;

Ntsia hlau ceev: 30--300rpm; Fais fab kis: Coupling

Gearbox: Siab torque reducer.

Kev txo qis thiab kev sib faib torque yog kev sib xyaw ua ke los txhawb kev tsim cov kabmob muaj peev xwm;

Cov iav yog ua los ntawm high-quality alloy steel.Tom qab carburizing thiab quenching, lub iav yog precisely hauv av.Qhov tseeb machining yog siab tshaj qib 5. Cov hniav hardness ncav cuag hrc60-65.Cov hniav profile thiab helix raug hloov kho kom ntseeg tau tias kev sib koom ua ke zoo tshaj plaws ntawm cov iav hauv qab thauj khoom, nrog lub suab nrov qis thiab cov kis loj loj;

Cov roj lubrication system feem ntau siv cov roj immersion lubrication thiab multi-point spray lubrication los xyuas kom meej tias txhua tus khub txav ib txwm lubricated;

Tshiab tsim sealing qauv thiab imported hom sealing nplhaib xyuas kom meej sealing kev ua tau zoo ntawm cov tswv yim thiab tso zis shafts;

Lubricating roj txias: phaj kub exchanger, circulating dej txias;Lubricating roj twj tso kua mis: built-in;

Twin ntsia hlau extrusion system: ntsia hlau yam:

Txoj kab uas hla ntawm cov ntsia hlau yog ¢ 75mm, uas txuas nrog lub mandrel los ntawm advanced involute spline;Khoos phib tawj optimized tsim, precision machining, zoo heev tus kheej tu thiab interchangeability;

Raws li cov khoom siv thiab kev siv thev naus laus zis, thiab nrog kev pab los ntawm ntau xyoo ntawm kev nplua nuj nyob rau hauv cov ntsia hlau teeb tsa R & D thiab tsim thiab software zoo, lub tsev thaiv kev sib xyaw ua ke tuaj yeem paub txog cov dej num ntawm kev xa cov yas, sib tov thiab sib tov, shear dispersion, homogenization, tso tawm devolatilization, siab lub tsev extrusion thiab lwm yam.

Cov khoom siv: zoo 38CrMoAlA nitriding hlau tom qab 72 teev nitriding kho;Screw rotation direction: tig nyob rau hauv tib txoj kev.

Khoom siv: ua los ntawm high-strength alloy steel high-strength quenching thiab tempering kev kho mob, hardness 300-350hb, composite forging, txhim kho lub zog thiab toughness, thiab xyuas kom meej cov kis tau tus mob yuav tsum tau ntawm cov ntsia hlau torque.

Lub tog raj kheej: Lub tog raj kheej siv cov qauv tsim, uas tuaj yeem ua ke dawb, precision machined thiab zoo sib hloov.Cov khoom siv: zoo 38CrMoAlA nitriding steel tom qab 72 teev nitriding kho;

Cov cua kub cua sov: hluav taws xob cua sov, cam khwb cia tooj liab thiab cam khwb cia txhuas cua sov yog siv, thiab cov cua kub kub

Lub raj mis txias: kiv cua txias tau txais yuav, nrog kev siv hluav taws xob tsawg thiab kev hloov pauv kub me me, uas yog qhov zoo rau kev ua tsiaj.Kev sib txuas nruab nrab lub cev:

Cam khwb cia hlau cov ntaub ntawv, precision machining, zoo kom ntseeg tau qhov ncaj ntawm kis tau tus mob thiab lub tog raj kheej thiab coaxiality ntawm kis tau tus mob cov ntaub ntawv tso zis ncej thiab ntsia hlau.

Lub tog raj kheej txhawb:

Cov qauv kev txhawb nqa ob npaug, kev ua haujlwm ruaj khov;

Lub axial displacement pressing mechanism yog tsim los ntawm kev txhawb nqa lub tog raj kheej thiab lub tog raj kheej kom tshem tawm cov deformation thiab vibration ntawm lub extruder vim thermal expansion ntawm lub tog raj kheej.

Lub tog raj kheej txuas bolts:

qib kub-resistant thiab muaj zog bolts yuav tsum tau siv rau kev sib txuas lub tog raj kheej

Base: Lub hauv paus yog nruj thiab nruab nrog lub tshuab tshwj xeeb damping ncoo, uas muaj kev vibration tsis tshua muaj suab nrov, kev ua haujlwm ruaj khov thiab tsis muaj lub hauv paus tshwj xeeb.

Lub tog raj kheej npog: Qhov sib cais hom stainless hlau rwb thaiv tsev npog ntawm txhua ntu ntawm lub tog raj kheej lub tog raj kheej yog txheej nrog cov ntaub ntawv rwb thaiv tsev, uas yog qhov zoo nkauj thiab yooj yim, txhim kho cov khoom siv hluav taws xob zoo, txo lub zog noj, txo qhov kub thiab txias ntawm lub tog raj kheej, thiab tiv thaiv scalding.

lub tshuab nqus tsev twj tso kua mis

Lub tshuab nqus tsev twj tso kua mis: lub nplhaib dej lub tshuab nqus tsev twj + lub hauv paus twj tso kua mis

Nqus condensing tank: stainless hlau nqus condensing sib cais tank, nruab nrog ntauwd phaj lim dej daim phiaj los pab kom pom cov impurities thiab volatiles.

Ob-theem qauv ntawm lub tshuab nqus tsev condensing tank tuaj yeem tswj tau tshem tawm cov dej, cov teeb meem tsis zoo thiab pov tseg.Lub tshuab nqus tsev kawm ntawv tsis tuaj yeem cuam tshuam thaum lub sijhawm tshem tawm.

Kev kub siab roj hmab hose yog siv, uas yooj yim rau disassemble thiab tuaj yeem ua lub luag haujlwm ntawm kev txuag hluav taws xob.

Txhua lub tshuab nqus tsev yog nruab nrog lub tshuab nqus tsev ywj pheej, uas muaj kev ywj pheej siab thiab tsis cuam tshuam rau ib leeg.Cov teeb meem hauv ib cheeb tsam yuav tsis cuam tshuam rau tag nrho cov kab ke.

Qhov tshwj xeeb tshaj qhov chaw nres nkoj tsim ua rau tsiaj tuaj yeem tawm ntawm qhov chaw nres nkoj yam tsis tau ntws mus rau hauv lub tshuab nqus tsev yeeb nkab thaum muaj cov khoom emission.Yooj yim rau disassembly thiab tu.

2.3 hloov pauv connector 1 daim

High quality nitriding steel (38CrMoAlA) khoom

nitriding kev kho mob, nruab nrog lub siab sensor qhov

Part II: screen changer thiab metering twj tso kua mis thiab T puab pwm

Ob chav kem npo hloov pauv 1 teeb

metering twj tso kua mis 1 teeb yam ntxwv

tag nrho cov reducers txais Dongli reducers los xyuas kom meej kis tau tus mob.

siab sensor thiab yaj yeeb nkab

yam ntxwv

sensor yog siv rau siab tau nyob rau hauv pem hauv ntej ntawm lub twj tso kua mis.

los ntawm kev tswj qhov system, lub siab sensor yog siv rau kaw-voj tswj ntawm extruder, uas tuaj yeem hloov kho lub extruder ceev thiab ntim ntim, thiaj li ua kom ruaj khov ntawm extrusion siab.

T-puab pwm 1 set

yam ntxwv

chrome plating thiab polishing.Hardness ntau dua HRC 55

txheej txheej: ib txheej

Khoom dav mm yim puas yim caum

Ntu 3: peb lub calender nrog txoj kab uas hla

1. peb yob calender1 teeb

yam ntxwv

hlua rub cov cuab yeej nres thaum muaj xwm ceev thiab Schneider hloov chaw nres tsheb ceev.

cov menyuam clamping thiab kev sib cais: lub tog raj kheej hydraulic raug kho, thiab zawv zawg siv cov kab qhia kev tsheb ciav hlau.

qhov chaw nres tsheb hydraulic txais kev tswj tsis siv neeg siab tsim, nrog lub siab tshaj plaws ntawm 8Mpa.

Kub tswj cov menyuam: dej cascade txias, siv dej chiller kom txias dej, (dej chiller xav tau kev xaiv)

roller gap adjustment servo lub cev muaj zog tswj, uas tuaj yeem teeb tsa nrog ib qho tseem ceeb hauv kev tswj hwm.(xav tau kev xaiv ntxiv)

lub calender tuaj yeem hloov kho nce thiab nqis, pem hauv ntej thiab nraub qaum.

Khoom dav mm yim puas yim caum

Khoom thickness Min.min mm xoom point tsib

Max.max mm ib point ob

Reducer Independent tsav Dongli reducer

Tsav tsav Variable zaus lub cev muaj zog kw ob point cuaj

Txawb lub cev muaj zog kw xoom point xya tsib

Part 4: tsheb laij teb / daim ntawv tshem tawm 1 teeb

yam ntxwv

Upper yob roj hmab yob, qis yob steel yob traction

kev tswj nruj yog pom tau hais tias ntawm traction thiab peb rollers, thiab kuj ntawm traction thiab winding.Thaum tag nrho lub tshuab ua kom nrawm thiab cov ntawv sib txawv yog tsim, kev tswj xyuas tsis tas yuav tsum tau, thiab qhov ceev tuaj yeem nce ntxiv rau tib lub sijhawm kom cov cuab yeej ua haujlwm tau zoo.Italian Jefferson hloov chaw sensor tau txais yuav.

laub khawm thaum muaj xwm ceev nres ntaus ntawv

nrog trimming system.Nws tseem yog nruab nrog ob lub pov tseg ntug winding khoom.

Reducer: Dongli hom

1. winder 1 teeb yam ntxwv

Moment winding

Dual / ob chav chaw nres tsheb

servo lub cev muaj zog tswj

Trimming unit.Ntug cov ntaub ntawv rov qab

Nrog trimming system.Thiab nruab nrog ob qho khoom siv khib nyiab winding.

Round riam txiav.

Torque lub cev muaj zog sau khib nyiab ntug

Tsis siv neeg zaj duab xis cia tshuab

thaum lub sij hawm tsis siv neeg yob hloov

Aluminium qhia cov menyuam: φ = 76mm, L = 1100mm nto xim av oxidation kho.

tuaj yeem khaws 16m nplooj ntawv;

Ntu 5: ob txoj haujlwm winder 1 teeb

Winding qauv: turret center, qhov sib txawv winding hom;

Rewinding muaj nuj nqi: Nws muaj ob txoj haujlwm ntawm kev sib cuag rewinding thiab qhov sib txawv rewinding;

PART 6 electric tsav system

Tsiaj hluav taws xob tsav system yog siv los muab cov cuab yeej tsav tsheb rau ntau yam tsiaj sib faib, nrog rau lub ntsiab extrusion unit, txias rau cov menyuam, traction unit thiab turnover ob txoj hauj lwm winder.

Thaum lub encoder tawm tswv yim yog saws rau lub kis tau tus mob ntaus ntawv, qhov ceev stability qhov tseeb yuav ncav cuag 0.1%.Kev tswj ceev thiab kev tswj siab yuav tsum tau ua tiav rau lub tshuab xa khoom ntawm extruder.High kis tau tus mob yuav tsum tau rau lub ntsiab extruder thiab txias cov menyuam,

los xyuas kom meej lub uniformity ntawm longitudinal kam rau ua ntawm daim ntawv PET.Floating rolls lossis nro sensors yog siv rau kev sib koom ua ke ntawm peb lub yob yob thiab lub tsheb laij teb.

Qhov kev teeb tsa ceev los ntawm cov tub yees txias mus rau chav traction yog nyob rau hauv kev sib raug zoo ntawm cov saw hlau los xyuas kom meej tias cov kab nrawm ntawm cov kab ntau lawm yog kev sib koom ua ke, thiab cov kab nrawm ntawm cov kab ntau lawm tuaj yeem muab los ntawm cov tub yees txias raws li cov khoom specification. , thiab tuaj yeem tsim arbitrarily.

Ntu 7 Ntawm kab ntawv tuav cov cuab yeej thiab lwm yam khoom siv pabcuam

1..On line silicone roj txheej system thiab.Silicone roj coated nrog 2m qhov cub

Khib ntug hauv internet rov qab system 2 poob lawm

2. Peb yob calendering tshav kub pauv

3. Dej cua sov thiab cua txias (muab los ntawm chiller)

Thaum tshav kub kub pauv yam ntxwv ntawm peb yob yob

4. Tsiaj siv cov khoom siv siv lead ua

5. 30HP Cua txias chiller

1. inline silicone roj txheej system thiab.Silicone roj coated nrog 2m qhov cub

Khib ntug hauv internet rov qab system 2 poob lawm

Nrog 2m qhov cub, Ib sab coated nrog silicone roj

4. Tsiaj cov khoom siv siv lead ua tshuab

5, 30HP Cua txias chiller

| PARAMETER Qauv | SYF-30 |

|

| |

| Lub tub yees muaj peev xwm | KW 50Hz / 60Hz | 92.6 ib |

|

|

| 110.66 Nws |

|

| ||

| Cov khoom siv hluav taws xob thiab cov khoom siv hluav taws xob | 380v 50 hz |

|

| |

| Cov tub yees | Lub npe | R22 |

|

|

| Tswj hom | Internalbalance expansion valve |

|

| |

| Lub compressor | Hom | Kaw vortex hom |

|

|

| Lub zog (Kw) | 27.4 ib |

|

| |

| Lub condenser | Hom | High efficiency tooj liab clad aluminium fins + tsis tshua muaj suab nrov sab nraud rotor kiv cua |

|

|

| Ntxuam hwj chim thiab kom muaj nuj nqis | 0.75kw * 3 |

|

| |

| Cua txias ntim (m³ / h) | 28290 ib |

|

| |

| Lub evaporator | Hom | Hom dej tank coil |

|

|

| Frozen dej ntim (m³ / h) | 22.07 Nws |

|

| |

| 26.48 Nws |

|

| ||

| Tank muaj peev xwm (L) | 580 |

|

| |

| Lub tshuab nqus dej | Lub zog (Kw) | 3 |

|

|

| Nqa (m) | 40 |

|

| |

| Tus nqi ntws (m³) | 25 |

|

| |

| Yeeb nkab diameter interface | DN 65 |

|

| |

| Kev ruaj ntseg thiab kev tiv thaiv | Compressor overheat tiv thaiv, tiv thaiv overcurrent, siab thiab tsis tshua muaj siab tiv thaiv, overtemperature tiv thaiv, theem sib lawv liag / theem tiv thaiv, tso pa overheat tiv thaiv. |

|

| |

| Mechanical qhov ntev | Ntev (mm) | 2500 |

|

|

| Dav (mm) | 1000 |

|

| |

| Siab (mm) | 1700 |

|

| |

| Input tag nrho lub zog | KW | 34.5 ib |

|

|

| Mechanical hnyav | KG | 1100 |

|

|

| Lus Cim: 1.Lub tub yees muaj peev xwm ua tau raws li: dej khov dej inlet thiab qhov hluav taws xob dej kub 7 ℃ / 12 ℃, cua txias inlet thiab qhov hluav taws xob cua kub 30 ℃ / 35 ℃. | ||||

| 2.Scope ntawm kev ua hauj lwm: khov dej kub ntau yam: 5 ℃ to35 ℃; khov dej inlet thiab qhov hluav taws xob kub sib txawv: 3 ℃ to8 ℃, ambient kub tsis siab tshaj 35 ℃. | ||||

| Tuav txoj cai los hloov cov kev txwv saum toj no lossis qhov ntev yam tsis muaj ntawv ceeb toom. | ||||