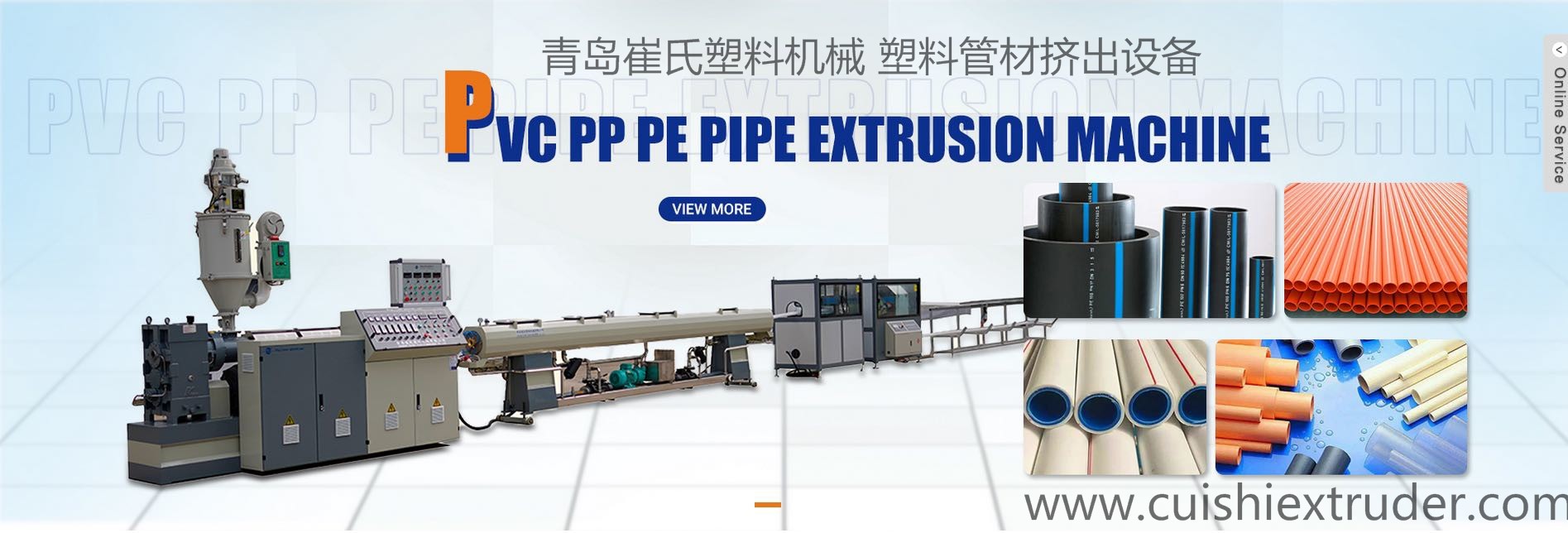

PVC Yeeb Nkab Extrusion Tshuab 63-160MM

PVC yeeb nkab Extrusion tshuab

PVC yeeb nkab extrusion kab yas conduit yeeb nkab extruder tshuab

Cov yeeb yaj kiab raws li hauv qab no, peb sim lub tshuab hauv 2009 xyoo

Peb cov yeeb nkab PVC ntau lawm kab txais kev siv tshuab siab heev

Peb tuaj yeem kho ntau yam PVC yeeb nkab ntau lawm kab raws li cov qauv yeeb nkab ntawm ntau lub teb chaws hauv ntiaj teb.Peb cov yeeb nkab txoj kab uas hla yog: 16mm-1200mm, los ntawm cov kav dej loj rau cov cables me me Peb tuaj yeem kho lub raj.

Peb cov yeeb nkab PVC cov kab ntau lawm tau nthuav dav thoob plaws ntiaj teb thiab muaj cov neeg siv khoom loj.Peb yuav muab tag nrho cov neeg siv khoom nrog rau ntawm qhov chaw teeb tsa, commissioning, kev cob qhia, thiab lwm yam.

Tsis muaj

| Qauv | Cov kav dej ntau | Extruder | Max tso zis | Max ceev | Tag nrho lub zog |

| PVC-50 * 2 | 16-50 hli | SJSZ65/132 | 250kg / h | 10m / min | 85 kwv |

| PVC-63 | 16-63 hli | SJSZ51/105 | 150 kg / h | 10m / min | 60 kwv |

| PVC-110 | 50-110 hli | SJSZ55/110 | 180 kg / h | 10m / min | 70 kwv |

| PVC-160 | 63-160 hli | SJSZ65/132 | 300 kg / h | 5 m / min | 90 kwv |

| PVC-250 | 110-250 hli | SJSZ80/156 | 400 kg / h | 3.5m / min | 120 kwv |

| PVC-315 | 160-315 hli | SJSZ80/156 | 400 kg / h | 3m / min | 160 kwv |

| PVC-450 | 250-450 hli | SJSZ92/188 | 700 kg / h | 1.5m / min | 200 kwv |

| PVC-630 Nws | 315-630 hli | SJSZ92/188 | 700 kg / h | 0.9m / min | 230 kwv |

PVC PIPE PLASTIC EXTRUSION MACHINE TECHNOLOGICAL PROCESS

DOUBLE-SCREW EXTRUDER---Tuag Lub taub hau & Mould & SIZING SET --- Nqus Dej Txias Tank --- TRACTION MACHINE --- Txiav Tshuab --- AUTOMATIC UNLOADING RACK

Chav tsev muaj conical ntxaib ntsia hlau extruder, PVC yeeb nkab extrusion pwm, lub tshuab nqus tsev calibration tank, haul-off tshuab, planetary saw txiav tshuab, tripping rooj, belling tshuab.

Thiab cov kab tuaj yeem nruab nrog cov cuab yeej ua kom tuab, lub tshuab computer ink-jet tshuab luam ntawv, crusher, shredder, pulverizer, dej chiller, cua compressor thiab lwm yam.

16-110mm PVC yeeb nkab ntau lawm kab

Nto moo Technical Parameters ntawm Txhua Saum toj no cov cav tov

1. ntsia hlau Loader feeder

| 1 | Screw load yeeb nkab txoj kab uas hla | mm | Φ110 |

|  | ||

| 2 | Ntsia hlau kav ntev | mm | 4 200 |

| 3 | Screw loader lub cev muaj zog | Kw | 2.2 |

| 4 | Screw loader loj | mm | 900 * 1100 * 960 hli |

2. Conical ntxaib ntsia hlau Extruder SJSZ80/156

Pwm rau PVC yeeb nkab IB SET

| Yam khoom | Kev piav qhia | Lus hais |

| tshwj xeeb tsim ua ntej txias qhov chaw tuaj yeem ua kom cov yeeb nkab du thiab ci ntsa iab Pwm 1. Cov khoom ntawm pwm lub cev yog Hlau 45 #, tawv kho thiab polished. 2.Material ntawm puab pwm qhov chaw yog 40Cr.

| ||

| 1 | OD | 63MM, 75MM, 110MM, 160MM |

| 2 | Khoom ntawm lub cev pwm | Hlau 45 # (zoo pwm steel) harden kho |

| 3 | Cov khoom ntawm lub puab qhov hauv pwm | 40Cr (superior pwm steel) harden kho |

| 4 | Khoom siv ntawm calibrator | Stannum tooj |

| 5 | Kev ntsuas siab (los yog yeeb nkab phab ntsa thickness) | Raws li cov ntaub ntawv koj xa tuaj |

4, Nqus Calibration thiab txias Tank

| Yam khoom | Kev piav qhia | SIB 160 |

| Muaj nuj nqi: calibrate lub sab nraud txoj kab uas hla thiab txias ﹡ tsis siv neeg qib dej tswj thiab dej kub ntse ntse zaub ﹡ hluav taws xob txee nrog tiv thaiv dej ﹡ forceful concentrated spraying water cooling with good cooling effect ﹡ lub tshuab nqus tsev twj tso kua mis thiab dej twj tso kua mis txais cov khoom zoo nrog ruaj khov ua haujlwm zoo. ﹡ Zoo meej pipeline tsim nrog impurity lim ntaus ntawv tuaj yeem ua kom tsis muaj qhov thaiv | ||

| 1 | Ntev | 6000 hli |

| 2 | Khoom siv ntawm lub tank | stainless hlau 304 |

| 3 | Hom cua txias | Dej Txau-pob qhov cua txias |

| 4 | Lub tshuab nqus tsev twj tso kua mis | 4kw * 1 teeb lub tshuab nqus tsev twj Thiab dej twj tso kua mis 3kw |

| 5 | Dej Pump zog | |

| 6 | Txoj hauj lwm sab laug thiab txoj cai hloov | Kev tuav tswj |

51 set ntawm Hauling off Machine

| NO | Kev piav qhia | Chav tsev | Lus ceeb toom | ||||

| ﹡ Pneumatic clamping, hloov kho zaus hloov kho ﹡ txais lub npe nrov lub tog raj kheej Vim txoj kab uas hla, nws tuaj yeem tsim ob, peb, plaub, rau, yim kab ntsig | |||||||

| Muaj nuj nqi: rub tawm PE yeeb nkab ruaj khov thiab synchronal nrog extruder ceev | |||||||

| 1 | Muaj pedrail ntev | mm | 1500 | ||||

| 2 | Clamping hom | Pneumatically | |||||

| 3 | Ceev Kho hom | Kev hloov pauv zaus | |||||

| 4 | Hauling Tsav Tsav | KW | 2.2 kwm | ||||

| 5 | Hauling Ceev | m/min | 0.5 ~ 20 | ||||

| 6 | PIPE DIAMETER | 16-160 MM | |||||

| tsis siv neeg plua plav dawb txiav, nrog ntsuas ntsuas muaj nuj nqi ﹡Saw hniav txais carbide hniav Lub tswb ceeb toom thiab suav cov khoom siv plua plav dawb 10, stacker Vim txoj kab uas hla, nws tuaj yeem tsim cov saw cutter lossis planetary cutter | |||||||

| Muaj nuj nqi: txiav HDPE yeeb nkab ntev ntev

| |||||||

| 1 | Cutter hom | Tsis siv neeg 'meter' suav cutter | |||||

| 2 | Tsim nyog txiav yeeb nkab txoj kab uas hla | 16-160 hli | |||||

| 3 | Txiav ceev | Synchronization, tsis siv neeg txiav hauv qhov ntev | |||||

| 4 | Lub cev muaj zog | KW | 2.2 | ||||

| 5 | Khoom ntawm Txiav Saw | Hlau alloy | |||||

| 6 | Clamping hom | Pneumatically Tsav | |||||

10, stacker

| 1 | Stacker | 6m |

| ||

Laser tshuab luam ntawv ib txheej